Gravity Walls

Gravity walls rely on the mass of the blocks to withstand the pressure of the earth. Without the need for reinforcement, it’s where Redi-Rock launched the industry of large, precast modular blocks in 2000 and continues to lead the way.

Why Choose a Gravity Wall?

Because it will allow you to...

Achieve Tall Heights

The massive weight of the blocks and patented knob and groove technology provide the resistance to hold back the earth to achieve design heights over 20 feet (6 meters) in certain scenarios without tiebacks.

Maximize Usable Space

Without the need for geogrid reinforcement and the excavation that comes along with it, you can construct walls closer to property lines, opening up more usable space.

Install Quickly with a Small Crew

With a properly-rated piece of machinery, crews of two to three can lift and set 5.75 - 11.5 square feet (0.5 - 1 square meters) with each block. That adds up fast!

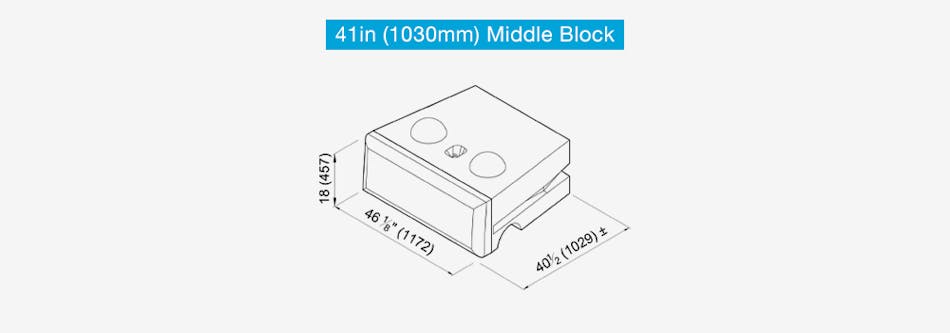

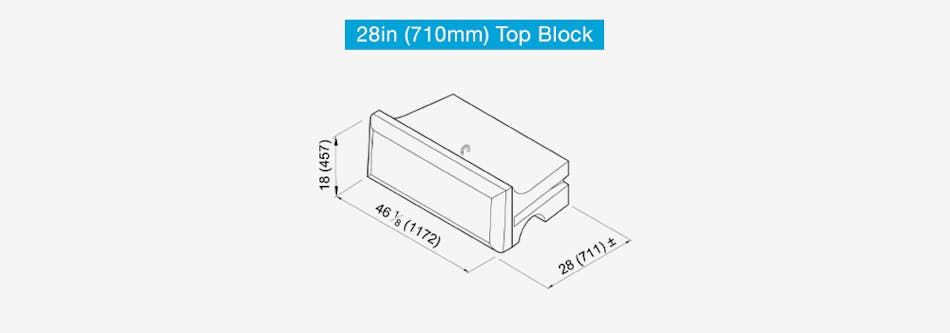

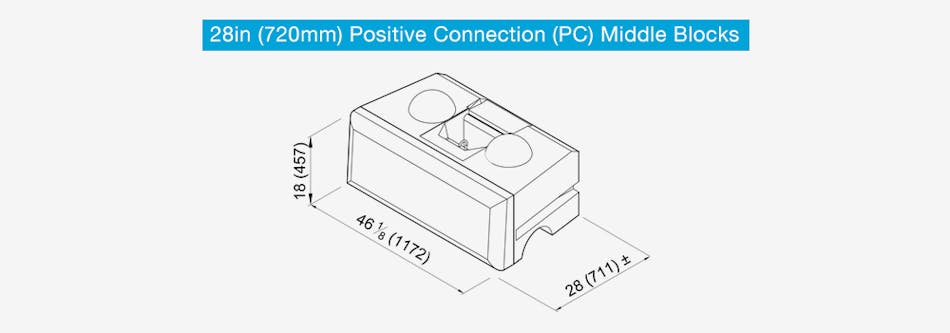

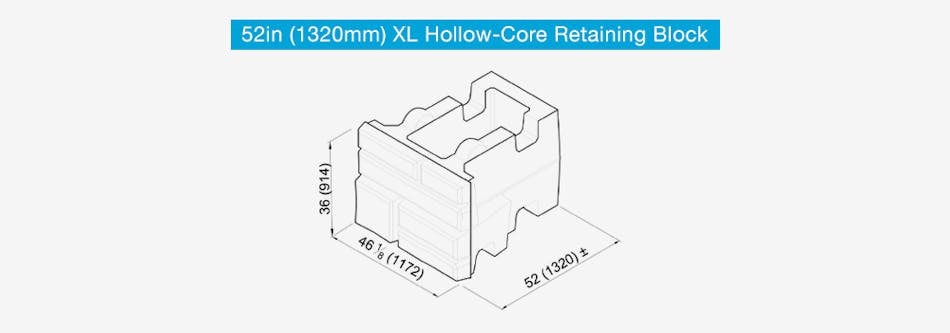

Commonly Used Blocks in Gravity Walls

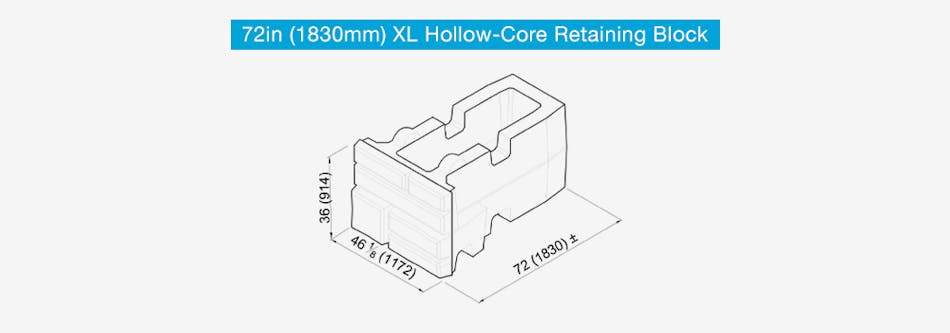

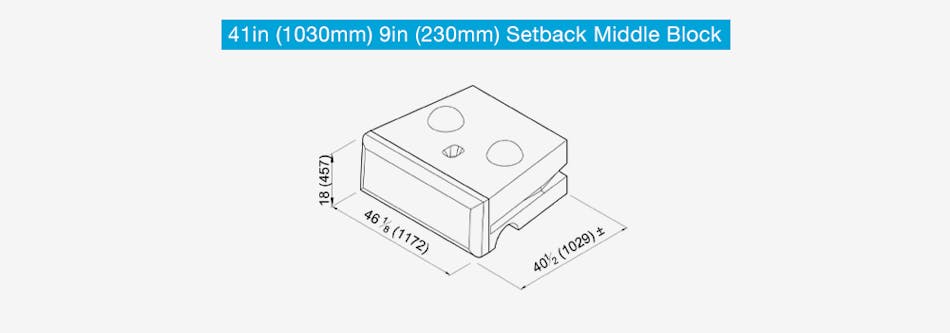

With solid and hollow-core blocks ranging in weight from 1160-4,840 pounds (530-2190 kg) and width from 28-96 inches (710-2440 mm), Redi-Rock can help optimize designs and speed up installation for tall gravity walls.

Don’t see what you’re looking for? Check out the entire Redi-Rock block library to view all the products available to help you solve your problems.

Gravity Wall Case Studies

Detention Basin Capacity Doubled in Houston Redevelopment Project

As part of Houston’s Memorial City Redevelopment Authority’s plan to improve traffic flow on Lumpkin Road, the capacity of the existing detention basin needed to be doubled. By using Redi-Rock 9-inch (230-millimeter) setback blocks supplied by Wilbert Vaults of Houston, engineers were able to overcome the tight footprint and poor soil conditions, while also meeting the project’s budget and schedule. Gravity walls helped the new L-shaped detention basin achieve a depth 19 feet (6 meters).

Two Highway Projects Save £16 million Using Redi-Rock Retaining Walls

After being approved by the United Kingdom's Highway Authorities Product Approval Scheme (HAPAS), Redi-Rock made its debut on two sections of smart motorway upgrades in 2020. Contractor Kier Highways and engineer Jacobs Atkins Joint Venture chose Redi-Rock gravity walls from Marshall’s CPM in order to avoid land acquisition and meet the varied demands of the project, while also providing £16 million in verified efficiencies for the 2.9 kilometers (1.8 miles) of retaining walls.

XL Blocks Help Achieve Heights Over 25-feet (7.5 meters)

When the excavation for a cut wall at John C. Tune Airport in Nashville, Tennessee, opened up a geotechnical can of worms, it was time to go back to the drawing board. The design team paired up the software and agility of the product line to solve the problems uncovered. The wall used over 800 XL Hollow-Core Retaining blocks from Redi-Rock of K.I.T. to overcome the unstable fill material and shorter than expected limestone rock cut, reaching a maximum height of 25.5 feet (7.8 meters) with the new gravity wall.

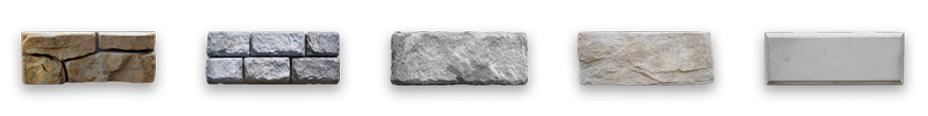

Available in Great Textures

With the appearance of natural stone, people will have to do a double take to realize it's concrete.

Gravity Wall Construction Details

From solid to hollow-core blocks, to batter angles, to site scenarios, the gravity wall construction details help you visualize the problem solving potential of Redi-Rock no matter what your project entails.

Want to Know More About Gravity Walls?

From roads and bridges to developments and residential applications, thousands of projects have used Redi-Rock gravity walls over the years. Watch the video to learn more about the Redi-Rock system and how a gravity wall might help you solve your site scenarios.