Great Lakes Hybrid Wall Saves Home from Rising Water Levels

Redi-Rock gravity, reinforced and freestanding walls seamlessly combine to provide beautiful solution for Lake Michigan homeowners

THE CHALLENGE

In March of 2020, Lake Michigan’s rising water levels threatened the loss of valuable property and damage to a lakefront home near Michigan City, Indiana. The shoreline erosion caused an existing dry-cast modular block wall on the property to completely fail, increasing the urgency for a durable, long-term solution that also aesthetically suited this high-end, lakeshore property.

Richard F. Gerdeman III, P.E. with Woolpert Chicago was challenged with designing a wall to protect the property and control the increased erosion due to the lake’s rising levels in the Great Lakes.

THE SOLUTION

An existing sheet pile wall was still serving a purpose as a first line of defense on the property. Although almost underwater, it continued to absorb some of the energy from the waves. This was enough for the secondary wall to be built without the need for temporary protection during construction. To best further protect the property, a hybrid wall was designed using both Redi-Rock XL Hollow-Core Retaining blocks and Redi-Rock Positive Connection (PC) blocks. The new wall would replace the failed drycast wall and extend the home's front terrace, adding value and visual appeal to the property along Lake Michigan. The owners chose Redi-Rock blocks with Ledgestone texture, adding distinctive appeal to their landscaping.

Redi-Rock is a large block retaining wall solution offering gravity, reinforced, and freestanding wetcast block products, all of which work together to provide solutions for various applications. Accessories like columns, steps, and caps coordinate perfectly with Redi-Rock retaining and freestanding walls to create a great-looking finished project.

Redi-Rock XL Hollow-Core Retaining blocks, weighing over 2 tons each, harness the power of gravity, allowing taller structures in narrower footprints. Combining XL blocks with Redi-Rock's Positive Connection (PC) System with geogrid reinforcement provides a unique and dynamic wall solution.

Utilizing wetcast blocks in this application was critical to avoid the inevitable water absorption and eventual deterioration that can occur with drycast products.

THE DESIGN

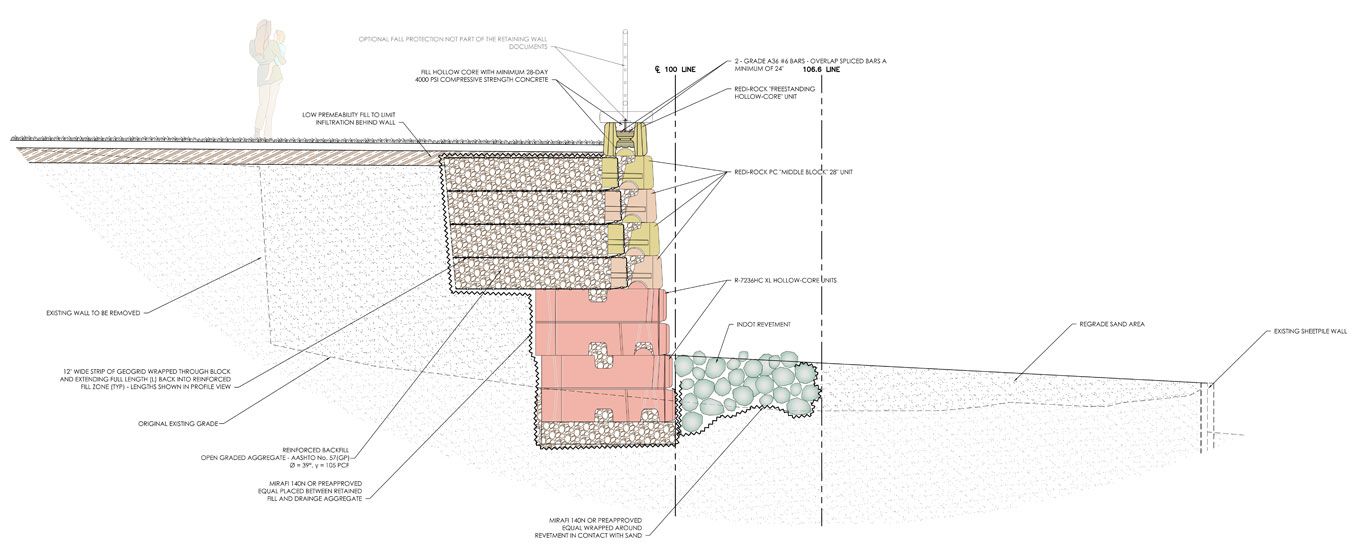

A hybrid wall design was selected to optimize permeability, shear strength, and structural integrity to prevent the formation of gaps and material loss, all critical in seawall applications.

The base of the wall, composed of 72in (1820mm) XL Hollow-Core Retaining blocks, provided stability to the 15-foot (4.6-meter) tall wall. The XL blocks also provided the endurance needed to withstand both water pressure and potential scour.

Redi-Rock 28in (710mm) PC blocks, which utilize a 12-inch (300-millimeter) wide strip of geogrid that wraps through the block sat atop the XL blocks. The PC blocks helped ensure proper anchoring to avoid any erosion on the back of the wall.

Gerdeman explained, "We could have utilized XL blocks for the entire wall, but the PC blocks allowed us to tie in the upper mass with grid and open-graded stone helped do that." He added, "The wall's 90-degree corner allowed the gridding to be overlapped, creating a very stiff configuration of the backfill, which allows the water to permeate through."

To complete the design, a final layer of Redi-Rock Freestanding Hollow-Core blocks created a 24-inch (0.6-meter) seat wall surrounding the terrace. The homeowners were thrilled to incorporate this functional feature into the structure itself.

A key factor in the success of the design was the selection and placement of the rock revetment in front of the hybrid wall. Rip rap, below and above grade, lined the wall's base to absorb wave energy and protect the structure. Gerdeman noted that the revetment chosen was ideal, serving two important functions. First, the rock itself and the slanted angle it creates, assists with the absorption of the wave pressure coming in. It also minimizes undertow scour of the wall blocks.

The existing sheet pile wall on the property, approximately 20 feet (6 meters) from the proposed Redi-Rock wall and running the width of the homeowner's property, was heavily considered in the design of the retaining wall. Gerdeman explained, "Having this sheet pile in front of the wall helped considerably. It helps keep some of the material in place and greatly diminishes wave energy. If it wasn't there, our design would be different; perhaps going deeper or using a stabilized aggregate behind the walls."

INSTALLATION

Although the project was the first Redi-Rock application for installer Bruce Woodruff of Woodruff & Sons, Inc. in Michigan City, Indiana, both the engineering team and block manufacturer praised his work for its accuracy and momentum. Mark Gorczyca, Redi-Rock Representative at Minnick Services in Fort Wayne, Indiana, noted, "The contractor did an impeccable job installing their first Redi-Rock wall in some of the toughest conditions."

After removing the failed drycast wall, the installation team dewatered the entire site to get good compaction with the wall's base stone. The XL Hollow-Core gravity blocks were then placed and the void spaces in and between them were filled with open-graded aggregate to facilitate appropriate water drainage behind the structure.

Redi-Rock PC reinforced blocks were then placed, each wrapped with Mirafi Miragrid 5XT 12-inch (300-millimeter) wide geogrid strips extending 7 feet (2.1 meters) to the back of the wall's reinforced fill zone.

The hybrid wall's combination of gravity and reinforced blocks allowed the design and install team to maintain a standard 5 degree batter, and the rock revetment placed in front of the completed wall provided a further barrier and angle for water pressure absorption.

THE OUTCOME

The design and installation teams agreed that Redi-Rock was the ultimate solution for this complex Great Lakes erosion application. A Redi-Rock hybrid solution provided the homeowners optimal wall strength and functionality without the necessity of a complete excavation or a sacrifice of aesthetics.

Not only are the homeowners thrilled with the outcome, but the success of this project prompted nearby lakefront homeowners and the neighboring City of Longbeach to utilize Redi-Rock for additional shoreline protection and beautification projects along Lake Michigan.

PROJECT DETAILS

Project: Lakeshore Drive #218 Customer: Homeowner Engineer: Woolpert Manufacturer: Minnick Services Installer: Woodruff & Sons Construction Location: Long Beach, Indiana Year Built: 2020

PRODUCTS FEATURED IN THIS CASE STUDY

Reinforced Retaining Wall Blocks - Build MSE retaining walls with the revolutionary Redi-Rock Positive Connection (PC) blocks

Redi-Rock XL Hollow-Core Retaining Blocks - new hollow-core design helps build taller walls in tight spaces while using less concrete

Ledgestone Texture - gives projects a random, stacked stone appearance

Freestanding Hollow Core Block - versatile freestanding units that can be filled with reinforcing steel and concrete for optimal strength.