Wisconsin DOT Uses Redi-Rock to Create Space for Pedestrian Path Near Large-Scale Highway Project

Six Redi-Rock retaining walls reach max height over 17 feet (5 meters) without reinforcement

THE CHALLENGE

In March of 2020, a large-scale street reconstruction and shared-use path project was undertaken by the City of Madison and the Wisconsin Department of Transportation (DOT). The city was challenged with multiple updates to Madison's bustling South Gammon Road from the Beltline Highway to Mineral Point Road. Construction began with street improvements including repaving, new curbs and gutters, repairs to adjoining sidewalks and public utilities, and upgrades to the street lighting and traffic signals.

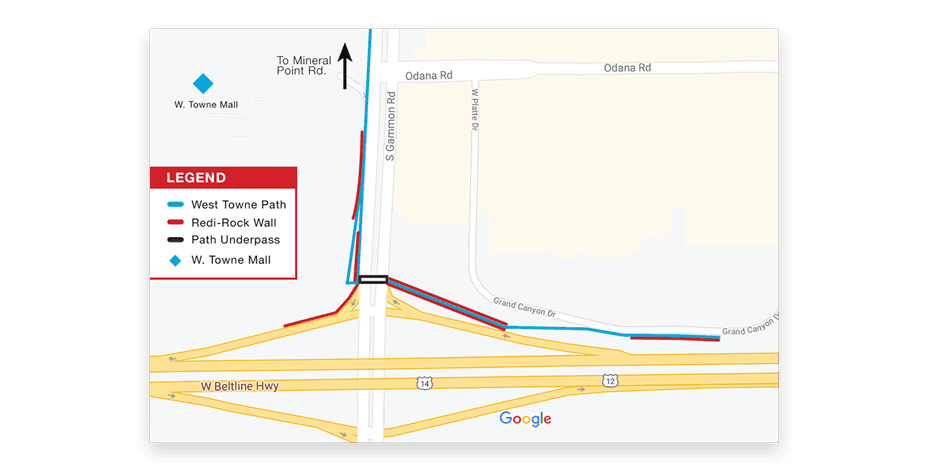

The scope of the project also included the construction of West Town Path, a shared-use path for pedestrians and cyclists traveling east/west through one of West Madison's busiest shopping districts. “[The construction of West Towne Path] is really important in the connectivity of our city,” explained Renee Callway, Pedestrian Bicycle Administrator with the City of Madison in a recent online video. “It connects employment and businesses, parks and residential areas that are all growing to make it easier for people to walk and bike for both transportation and recreation.”

The project engineering team had to produce a retaining wall solution that held back the earth along the new path, and one that could be built around a host of nearby utilities. The construction of the walls would have to be performed in tight spaces to avoid road closures and extreme traffic congestion in the area.

Six Redi-Rock retaining walls came together to create the space adjacent to the Beltline Highway for West Towne Path near West Towne Mall in Madison, Wisconsin.

Six Redi-Rock retaining walls came together to create the space adjacent to the Beltline Highway for West Towne Path near West Towne Mall in Madison, Wisconsin.

THE SOLUTION

Wall design engineer, Clint Hines, P.E., principal of JC Hines & Associates, collaborated with the civil engineering team at Strand Associates to create a design calling for six retaining walls for the new pedestrian path and underpass in this expansive mixed-use project. Each of the walls contained a unique configuration of Redi-Rock precast modular blocks, all in Cobblestone texture to add a natural aesthetic to the surrounding roadways and shopping district. Redi-Rock supplier, Brown Precast, provided the materials needed for the massive project containing over 2,500 blocks, equating to over 15,000 square feet (1393.5 square meters) of retaining walls.

Gravity and MSE wall sections in the Cobblestone texture came together to create a seamless end result.

Gravity and MSE wall sections in the Cobblestone texture came together to create a seamless end result.

THE DESIGN

The two 15-foot (4.5-meter) high wing walls on the west side of the path underpass were to be constructed with the Redi-Rock Positive Connection (PC)/MSE wall solution utilizing geogrid reinforcement wrapped through the core slot of each block. To navigate a storm manhole behind the highest point of one of these reinforced walls, the design plans were altered to construct the first 50 feet (15.2 meters) of wall as a gravity structure. With this versatility, Redi-Rock wall solutions allowed for the myriad of unexpected scenarios and change orders that often occur in such large civil projects.

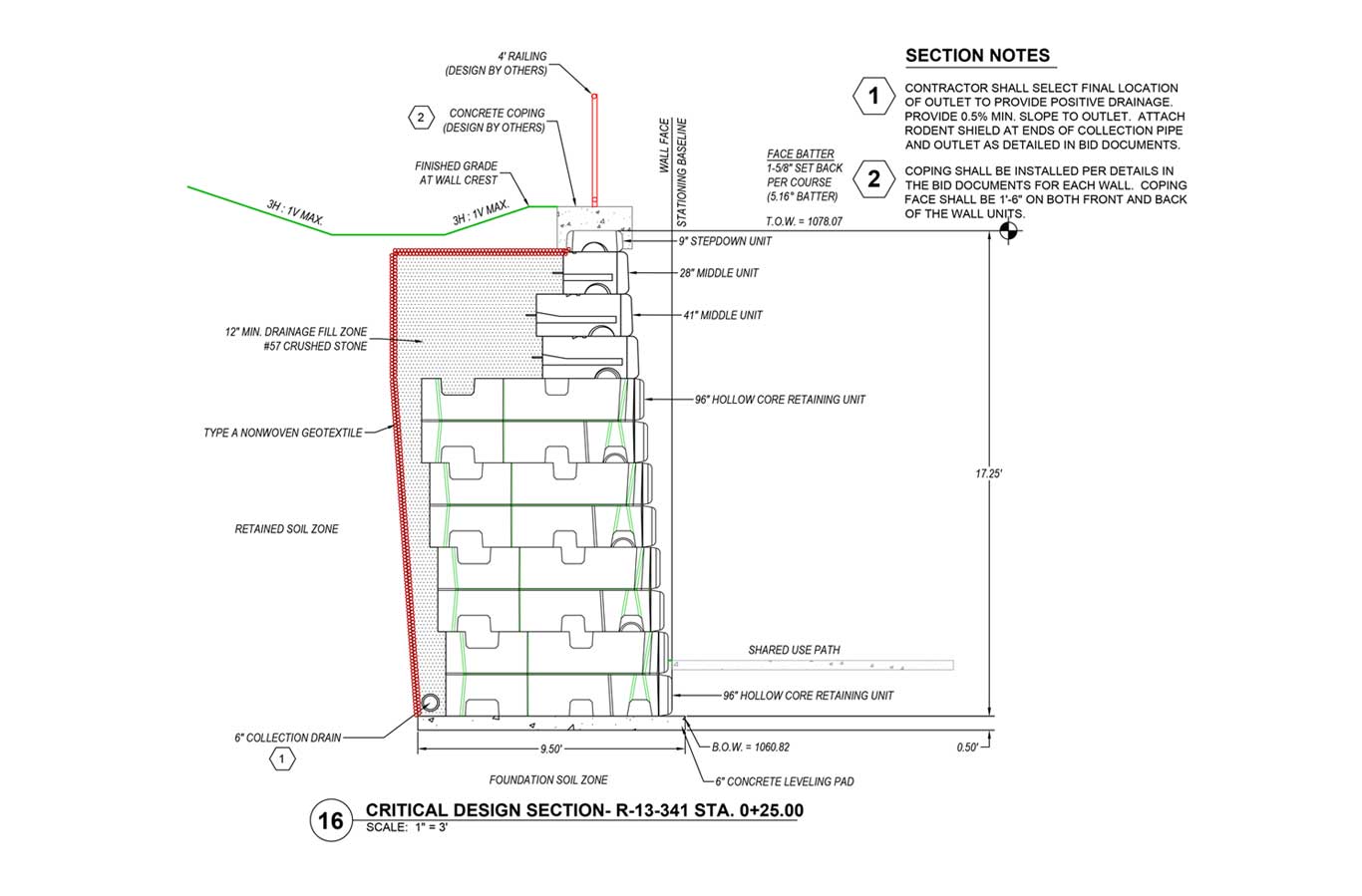

The retaining walls leading to the east side of the underpass were designed as Redi-Rock gravity walls to hold back the earth as the path sloped downward to the tunnel entrance. A combination of 28in (710mm), 41in (1030mm), and 60in (1520mm) solid, 5-degree batter blocks and Redi-Rock’s 96in (2440mm) XL hollow core units were called for to achieve wall heights of over 17 feet (5 meters) without reinforcement. The three additional XL block sizes round out the Redi-Rock system to help build taller walls in tight spaces while using less concrete.

“A high voltage electric line presented some challenges for the design of the 17.25 foot (5.25 meter) gravity wall,” noted Hines. “The contractor installed temporary shoring to support the excavation, but the wall needed to be designed with blocks large enough to support the total design load of the native soil and the surcharge with the minimum amount of drainage stone behind the blocks.”

“To accomplish this,” Hines continued, “we turned to the Redi-Rock XL units, which provided the structural capacity needed at the taller wall height and transitioned well with the standard Redi-Rock gravity wall units needed in the rest of the wall.”

Redi-Rock 96-inch (2440 mm) XL Hollow-Core retaining blocks were utilized to accommodate utilities behind the wall and to achieve wall heights in excess of 17 feet (5 meters) without using reinforcement.

Redi-Rock 96-inch (2440 mm) XL Hollow-Core retaining blocks were utilized to accommodate utilities behind the wall and to achieve wall heights in excess of 17 feet (5 meters) without using reinforcement.

The Redi-Rock PC solution was to be utilized to construct two additional walls; one 488-foot (148.7-meter) long lining West Towne Path as it slopes up from the underpass north along South Gammon Road, and one 628-foot (191.4-meter) long lining the path between the Beltline and Grand Canyon Drive.

The design included topping all six walls with a Redi-Rock garden top blocks to facilitate cast-in-place coping. Masonry anchors were embedded in Redi-Rock hollow garden top blocks and extended above the wall as the concrete coping was cast. The coping tied seamlessly into South Gammon Road's adjoining walkways, accommodating railings where necessary, and maintaining visual consistency throughout the project. All walls were designed with the standard 5 degree batter, with 1 ⅝ inch (41.3 millimeter) setback per course.

“The Redi-Rock design software was tremendously helpful in the design of this project,” explained Hines. “The ability to quickly change between reinforced and gravity design approaches, and then model them in 3D, helped us optimize our designs to fit within some pretty restrictive construction limits.”

Custom garden top blocks with masonry anchors embedded in them were used to tie into the cast-in-place coping for the walls.

Custom garden top blocks with masonry anchors embedded in them were used to tie into the cast-in-place coping for the walls.

THE INSTALLATION

The crew at Edgerton Contractors began with the construction of two parallel Redi-Rock gravity walls lining the pedestrian path east of South Gammon Road and abutting the opening of the precast pedestrian path tunnel. Redi-Rock 60in (1520mm) solid blocks were laid for the base of the 13.5-foot (4.1-meter) long south wall and Redi-Rock 96in (2.4-meter) XL Hollow-Core blocks composed the base of the north wall to accommodate surrounding utilities and achieve a height of 17.25 feet (5.2 meters). Both 41in (1030mm) and 28in (710mm) solid gravity blocks were used to complete the walls, each spanning approximately 300 feet (91.4 meters) in length.

The remainder of the walls utilized the Redi-Rock Positive Connection (PC) wall solution with middle and bottom 28in (710mm) PC units and 12-inch (300-millimeter) wide Miragrid 5XT and 10XT geogrid strips threaded through the blocks. Redi-Rock reinforced walls not only benefit from the sheer size of their precast modular blocks, but also from stabilizing the soil behind the wall, in this case using geogrid strips extending 12.5 feet (3.8 meters).

All Redi-Rock blocks are precast with patented knob and groove technology which creates optimum interface shear resistance and greatly simplifies construction, saving considerable time on this large-scale project.

Edgerton Contractors installed six Redi-Rock retaining walls on the Wisconsin DOT / South Gammon Road project in 2020. The patented knob and groove technology helps expedite installation of gravity walls using massive precast modular blocks.

Edgerton Contractors installed six Redi-Rock retaining walls on the Wisconsin DOT / South Gammon Road project in 2020. The patented knob and groove technology helps expedite installation of gravity walls using massive precast modular blocks.

THE OUTCOME

Hines praised the success of the Redi-Rock project, noting, “When utility conflicts arose during final plan review, the versatility and the range of products available in the Redi-Rock system allowed us to modify our design to accommodate the new conditions. Ultimately, we were able to deliver a retaining wall design that met the structural requirements of the project and also maintain the continuity of the aesthetic appearance of the final construction.”

On project completion, not only did Madison provide a huge upgrade to a highway in one of its highest-traffic shopping districts, but also made safe pedestrian traffic possible with its innovative integration of pathways and sidewalks. Redi-Rock retaining walls provided the long-term solution desired, saved project resources, and added a beautiful natural aesthetic. The improvements will facilitate a safer and more fluid flow of vehicle and pedestrian traffic through Madison's West Towne Mall shopping district.

PROJECT DETAILS

Project: Wisconsin DOT / South Gammon Road #220 Engineer: Clint Hines, P.E. Manufacturer: Brown Precast Installer: Edgerton Contractors Location: Madison, WI Year Built: 2020

PRODUCTS FEATURED IN THIS CASE STUDY

Gravity Retaining Wall Blocks - Massive, one-ton Redi-Rock gravity blocks rely on the sheer mass of each block to hold back the earth.

Reinforced Retaining Wall Blocks - Build MSE retaining walls with the revolutionary Redi-Rock Positive Connection (PC) blocks.

Redi-Rock XL Hollow-Core Retaining Blocks - at twice the height of standard Redi-Rock blocks and available in widths of widths of 52, 72, and 96-inches (1,320, 1,820, and 2,440 millimeters), the hollow-core design helps build taller walls in tighter spaces while using less concrete.

Cobblestone Texture- Redi-Rock Cobblestone blocks feature a great stacked stone aesthetic with the appearance of six smaller blocks.